Downloadable Info & Data

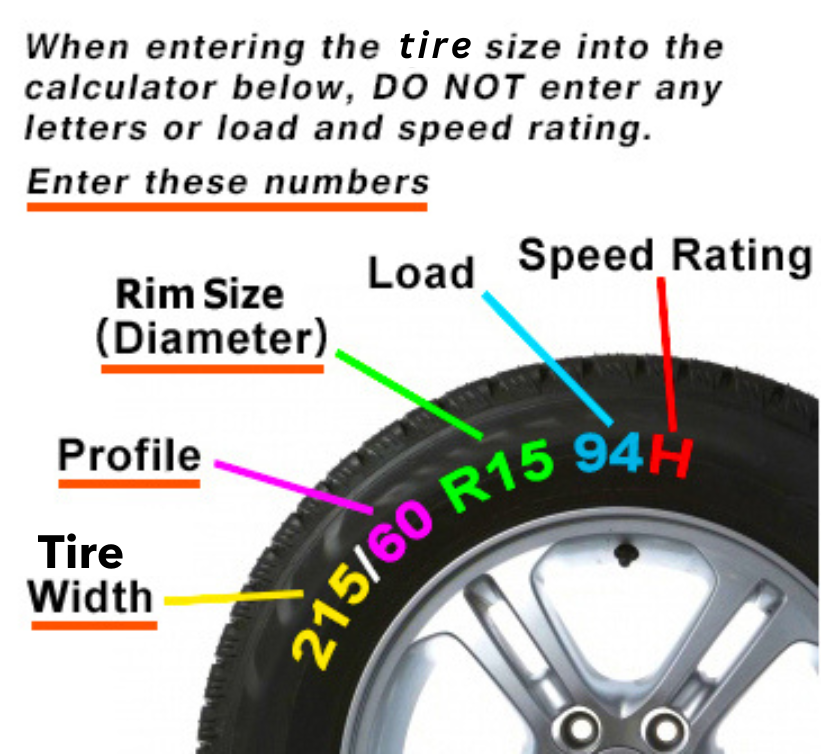

The three Calculators below are for calculating the number of PunctureSafe units required in:

A/… Light high speed vehicles such as Cars, Vans, Touring Caravans & Trailers

B/… Motorcycles & Scooters

C/… HGVs – On Road use. For On/Off Road use, add 25% to the figures calculated. Please enter numbers only in all the boxes and no letters.

Please refer to the downloadable charts above for agricultural and construction vehicles because those tire sizes cannot be calculated with the online calculator.

Conversion to milliliters is also displayed so as a comparison can be made with similar products to show that considerably less PunctureSafe is required to do a much better job than other products that require a lot more sealant installed. As an example, a 22.5 inch tire on a large articulated HGV would only require one and a quarter litres for complete inner tyre coverage. There are 34 units in a litre of PunctureSafe.

Cars, Vans, TouringCaravans & Trailers

Motorcycles &Scooters

HGVs. - For On/OffRoad use add 25%

What is PunctureSafe?

A tire life extender/conditioner & permanent puncture prevention treatment

PunctureSafe is a special blend of polymers that coats and clings to the inner tire. PunctureSafe is a “permanent” puncture prevention treatment and tire life extender/conditioner. Previously available products (and most current ones) have simply “fallen apart” at speeds of 40 mph and over because they were manufactured for the construction industry slow vehicles, but eventually made their way into the high-speed markets creating problems. PunctureSafe is not a get-you-home product. It is applied before the puncture occurs, and permanently seals punctures as they happen. Once installed, PunctureSafe not only seals punctures, it conditions the inner casing, preventing porosity leaks caused by tiny holes and cracks. In other words, after installing Puncturesafe the tires maintain correct air pressure, and the need to regularly top up with air is virtually eliminated, and with correctly inflated tires you get better fuel economy, your tires also run cooler eliminating that problem of heat build-up. Tires treated with PunctureSafe last considerably longer, and cooler tires are also less susceptible to punctures. PunctureSafe is water-based for easy clean out if ever you need to do this and is installed in minutes through the tire valve with very little air loss and without removing any wheels.

What makes PunctureSafe different from tire sealants that do not work?

Technology! Sealants have caused many problems that we at PunctureSafe have addressed. Using a highly evolved mixture of polymers, we have devised a product that is more than capable of working in harmony with today’s modern style of vehicles. We use advanced chemistry in our process that bonds the molecules of the sealant together at speeds up to 150mph. Previously available products, and most current ones, have simply “fallen apart” at around 55-65mph.

Performance and abilities and does not diminish with speed distance or time

PunctureSafe does not have any of the failings that previous and many present products have. Apart from drying and balling up in the tire, the biggest failings of traditional tire sealants in a high-speed tire, were the inability to seal small holes, but the ability to seal a large dangerous hole or cut, because they contained large chunks of chopped-up rubber. Whereas PunctureSafe contains only tiny strands of coarse surface synthetic fibers that are stronger than steel when they interlock tightly together, but will only positively seal small holes caused by puncturing objects up to 6mm in diameter, but only in a hole that is in the tread area of the tire, and that is shrinking in size because there is no cord damage (rubber recovery), which is 95% of today’s punctures in high-speed vehicles. Anything bigger, or in the sidewall, with or without cord damage, and the PunctureSafe fibers just slowly bleed through the hole, giving a controlled deflation, and usually with a halt or abrupt slow down in air pressure loss at the lower pressures of 10 to 15 psi (depending on cord damage) which prevents damaged rims, and helps the driver maintain control possibly enabling the continuation of the journey to remove the vehicle from a possibly dangerous location.

Through our extensive research and development, our proprietary formulation has evolved far beyond that which is commonly known as a tire sealant – PunctureSafe is a tire safety system outstanding at permanently sealing punctures and a true tire life extender. PunctureSafe converts any pneumatic tire into a self-sealing tire that will maintain air pressure. Puncturesafe has the ability to coat more of the inner surface of a tire and rim without succumbing to shear and stress associated with a centrifugal force that is created within a high-speed rotating tire. PunctureSafe’s attributes are unparalleled in the history of pneumatic tires.

The PunctureSafe Research & Development Team developed an unrivaled proprietary process that has yet to be duplicated.

How it works

Once PunctureSafe has been installed, it lies dormant at the bottom of the tire until the vehicle is first driven. Once driven a minimum of three to five miles, PunctureSafe disperses throughout the inner tire and forms a coating on the inner surface of the tire assembly. In order to get sidewall coverage it takes 1500+ miles to activate the FlexxaGel to adhere to more of the inner tire. The flexing of the tire and the normal heat build-up allows PunctureSafe to seek out and eliminate common air loss problems (referred to as porosity, air migration, and bead leaks). Puncturesafe then transforms the tire assembly into a sealed air chamber, capable of maintaining proper air pressure. Thereafter, PunctureSafe conditions the rubber in order to retard dry rot and aging (hardening) of the casing. One treatment will provide additional longevity and cooler running tires for the legal tread life of the tire.

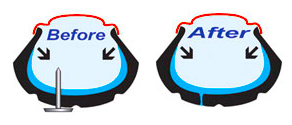

The advanced technological sealing capabilities of PunctureSafe stand on guard to seal punctures as they happen. When a tire is punctured, PunctureSafe coats the surface of the penetrating object, thus preventing air loss.

When the puncturing object is removed, the rubber recovers and the wound immediately closes, escaping air-siphoning PunctureSafe into the puncture. The fibers entwine to create a clot that prevents any additional air from escaping. As the rubber recovers, the puncture closes and the strength of the tire holds the seal in place. The specialized polymers and fibers form the seal, thereby producing an airtight seal. The small amount of PunctureSafe that penetrates through the puncture, past the belts, and out through the tread area is referred to as a seal. Once exposed to the atmosphere, the seal begins a systematic cure (another proprietary attribute from the PunctureSafe R&D Team). As the seal cures, it makes a positive secure seal that is impervious to water, which totally protects the belts and inner casing from outside contaminants and corrosion.

PunctureSafe’s proprietary formulation is one of our closely guarded secrets, which allows PunctureSafe to withstand heat and the shear forces created within a rotating tire. The thixotropic polymers stretch and recover under mild to severe exposure to adverse forces and continuously cling to the inner tire. The ability to coat the inner surface against adverse conditions and centrifugal force is the reason that PunctureSafe will not adversely affect a balanced tire assembly and does not lose the ability to provide protection for the tread life of the tire.

PunctureSafe’s abilities & performance are not diminished by speed, distance, or time.

Sealing capabilities

If the tire’s integrity is weakened to a point where the tire and casing are unsafe, PunctureSafe is designed to bleed and slowly release air pressure in a controlled way if the puncturing object has severely damaged the inner structure.

PunctureSafe will not hide or mask a dangerous puncture regardless of how small the damage may be. If the integrity of the casing has been breached and safety becomes an issue, PunctureSafe is designed to allow air to escape in a controlled manner.

Coating and conditioning

PunctureSafe coats and clings to the inner tire conditioning the inner surface, and eliminating air migration caused by porosity and bead leaks.

It is imperative that the proper amount of PunctureSafe be installed in a tire (refer to the application chart/calculator). In order for PunctureSafe to function, the vehicle should be driven approximately 3 to 5 miles (it is not required to immediately drive the vehicle). This initial driving allows the tire to warm up and for PunctureSafe to distribute. Puncturesafe will cover the crown area in the first few miles, but it will take another 1500+ miles for the FlexxaGel to activate giving more coverage of the sidewall. Unlike conventional tire sealants, PunctureSafe has been developed to prevent migration from the sidewalls and the tread area at high speeds. Once the initial driving/usage period has been attained; Puncturesafe covers more of the inner surface of the tire.

PunctureSafe is a proprietary liquid coating that never deteriorates within the tire and will continuously stand on guard to protect tires against air loss for the legal tread life of the tire.

Will not cure or harden inside the tire

People often ask, “If PunctureSafe cures from exposure to outside air, then why doesn’t it cure by the air inside of the tire?” PunctureSafe transforms the tire and rim into a sealed air chamber. As the vehicle is driven and the temperature of the tire increases, a portion of the liquid base vaporizes within the tire assembly’s inner air cavity, as the tire cools, the moisture condensates back into the formula. The inside air actually becomes part of the system. The sealed air chamber prevents outside air from entering or inside air from escaping. Constant air pressure maintenance is not required.

Positive secure seal

When a tire is punctured, PunctureSafe is forced against and around the puncturing object by the inner air pressure, thereby preventing air from escaping. If the puncturing object is thrown out of the tire by centrifugal force or is pulled out, the inside air forces PunctureSafe into the puncture and immediately stops air loss. Special fibers entwine, forming a seal, then as the rubber recovers, aided by the tire flexing as it rotates, the inner air pressure forces the seal well into and through the puncture. Once PunctureSafe is exposed to the outside air, a curing process begins. The cured seal extends well into the puncture, thus providing a seal that is impervious to water (rain, snow, mud, etc.). As this seal cures, it is transposed into a permanent rubberized seal, protecting the inner casing and steel belts against contaminants entering the puncture.

The 80/20 syndrome

The seal is permanent because of two very important attributes of PunctureSafe:

A). There is no shrinkage of the drying polymer in the puncture because the gel is 80% polymer and only 20% liquid, because we do not use cheap ingredients that bind huge amounts of water. It is common for similar products to be the other way around with 20% polymer and 80% liquid.

B). The gel dries and cures to a firm, flexible, and rubber consistency which means the seal will flex with the puncture causing no air loss over time.

It is a fact that any viscous wet compound containing fillers, such as fibers and rubber particles, will initially seal a puncture whilst in the wet state because wet compounds will flex with the tire in the puncture, but the problems arise in many of these “so-called” similar products when the liquid escapes out of the puncture into the atmosphere causing the compound in the puncture to dry back to the original ingredients. When dried out these “so-called” similar products will vary in looks and texture because of the vast difference in ingredients used in these tire sealants such as Biscuit, Plasticine, Putty, Paper, Crystalline, Flour, Sticky Pristick, Bluetack, cement, clay, etc. The descriptions and looks of many of these dried-out products are never-ending, but it is a fact that in the wet state, these gloopy tire sealants all look very similar, except in color, but that is where the similarity ends. Many of these compounds that have usually been formulated by people without any knowledge of chemistry whatsoever, once dried out in the puncture will eventually fail, resulting in a flat tire, sometimes within days or just weeks after the initial puncture.

The eight images directly below are of PunctureSafe and six “so-called” similar products that have been allowed to dry out in a laboratory oven at 50 degrees C for 24 hours. When fully dry, PunctureSafe has very little shrinkage and is flexible and firm which are the attributes required of a dried-out tire sealant in the puncture to permanently seal the puncture, especially in the low-speed market where punctures can be caused by puncturing objects up to 30 mm in diameter. It is our trademarked secret ingredient “FlexxaGel™” that gives PunctureSafe so many of its quality attributes.

What is The Difference at a Glance?

- Seal punctures permanently and for the life of the tire.

- Will give you a controlled deflation if the integrity of the tire has been compromised.

- Will cover more of the inner tire “at high speeds” to prevent porosity in the tire and stop bead leaks-Requires advanced chemistry.

- Will not pile up in a narrow band down the center of the crown area owing to centrifugal forces-this is a common problem with many sealants and the advanced chemistry required to prevent this is our closely guarded secret.

- Will seal punctures over more of the crown area” owing to PunctureSafe’s “better inner tire coverage.”

- Will not seal punctures in the thin & flexing sidewall, but will give a tell-tale sign with a controlled and slow deflation.

- Will help extend tire life because of a much cooler inner tire. Heat build-up is removed by conduction away from the inner tread area to the rim, because of better inner tire coverage. Plus, cold tires are less susceptible to punctures. (Rubber is a poor conductor of heat).

- Will help extend tire life as better coverage over the “inner tire” eliminates porosity giving optimized tire pressures, with the added benefit of improved fuel economy and safer vehicle handling.

- Will be manufactured using heat” in an intricate process with over 15 polymers to give a solids content of 80%, but only 20% liquid, rather than 80% liquid and only 20% solids, which are common with sealants mixed cold with as little as one or two polymers – You cannot achieve the attributes you find in PunctureSafe with only one or two polymers or without applying heat and the principles of chemistry during the manufacturing process.

- Will cure the puncture with a firm and flexible rubbery plug. As opposed to something resembling sticky modeling hard clay and common with tire sealants formulated with just one or two polymers. These simple sealants initially seal punctures, but then fail as the plug dries and shrinks because of heat. This is because simple tire sealants with a high water content that can bind fiber and rubber particles whilst still in their liquid state initially seal a puncture in a tire but fail as the tire sealant plug dries and shrinks.

- Will be water-based for quick and easy cleanout from the tire.

- Will definitely not vapourize or steam in a warm tire causing the tire pressure to increase to a dangerous level – Requires advanced chemistry to achieve a complex azeotropic liquid base that increases the boiling point of liquids to prevent steaming. Similarly, when water binds the polymer chains via hydrogen bonding it increases the surface area, which causes the water to evaporate out of a polymer at the slightest increase in temperature. Our unique chemistry prevents this from happening.

- Will not over any length of time, break down or dry up inside a high-speed tire – Requires advanced chemistry applied with heat to achieve this.

- Will not over time lose any viscosity in the tire.

- When heat and stress are applied to water-based polymers inside a high-speed tire, the polymers rapidly thin within a few thousand miles in a process called hydrolysis (decomposition of the polymer chains owing to a chemical reaction with water, during which molecules of water are split into hydrogen cations). Our unique chemistry prevents this from happening.

- Will not ball up inside the tire. Owing to the large difference in specific density between the heavy liquid polymer and the significantly lighter fiber and rubber particle solids, centrifugal force normally causes these lighter particles to be forced in a reverse direction and collect on the inner surface of the polymer in clumps. Our unique chemistry prevents this from happening.

- Will not run to the bottom of the tire in a stationary vehicle.

- Will be thermally stable at speeds of up to 155 mph-very rare.

- Will not rust or corrode rims.

- Will condition the inner tire.

- Will not void tire manufacturers’ warranties.

- Does not contain Ethylene Glycol, an extremely toxic anti-freeze.

- Is nontoxic – A result of years of Research & Development.

- Will always comply with Health and Safety regulations in the US.

Why Does PunctureSafe Not Cause a Balance Problem?

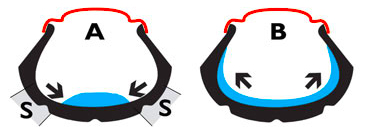

The law of physics is quite precise, especially when it comes to liquids in a centrifuge. They will be forced in the direction of the forces, which in a moving tire is in the opposite direction from the wheel rim. A tire on a moving vehicle is a centrifuge and tire sealants inside a tire will obey these laws and be forced outwards to the highest point which is the center of the crown area as shown in diagram A below. As a vehicle gathers speed, tire sealants form a narrow band in the center of the crown area of the tire and the width of this band is dependent on the vehicle’s speed. At only 2mph, that band will be narrow covering approximately only 70% of the crown area, but as the vehicle’s speed increases to normal driving speeds of 20 to 60 mph, that band narrows significantly as the centrifugal forces increase. With these higher speeds, a tire sealant will begin to pile up in a bulky mass as extreme forces come into effect as shown by the arrows in diagram A. At these high speeds and with these conditions balance problems are prevalent. Sideway movement of the vehicle will temporarily cause a little sealant to creep across the shoulder area, but forward movement will immediately bring it back again. Also, because of the low crown coverage, even at speeds of only 2 mph, there is no protection against punctures in the shoulder region of the tire as shown in the grey shaded area marked S in diagram A.

PunctureSafe covers more of the inner tire “at all speeds.” As shown in diagram B below, coverage continues to get better the more miles the vehicle covers. As the vehicle’s speed increases, PunctureSafe’s thixotropic polymer gel stretches over the inner tire giving good coverage with a very thin layer no thicker than 2 or 3mm, and that is the reason balance problems do not occur with PunctureSafe. The PunctureSafe gel will relax in a stationary vehicle covering less of the inner tire. We at PunctureSafe have managed to achieve this in a process using very advanced chemistry not normally found in any other tire sealant. Our proprietary process which gives PunctureSafe these attributes and other beneficial properties is our most closely guarded secret which no other manufacturer has yet managed to duplicate. You need very sophisticated equipment to achieve this level of chemistry which we have built entirely to our specifications. Large rubber particles of 1 mm in size normally found in tire sealants are also a big cause of balance problems. We granulate our own rubber particles right down to between .2mm and .4mm for inclusion in our high-speed grades.

Safety Features: The Main Safety Features of PunctureSafe High

Performance, High Speed Grade

Outstanding at sealing punctures

PunctureSafe’s makeup is 80% polymer and 20% liquid which means it is a very high solids content and dries to a flexible rubbery plug in the puncture without any shrinkage. The polymer gel suspends a special mix of highly fibrillated fibers and granulated rubber fillers which contribute to Puncturesafe’s sealing abilities. So once the seal is in place, it is permanent and will not fail at a later date.

Seals only the smaller, less harmful punctures

PunctureSafe does not have any of the failings that are inherent in many previous and most of the current products available on the market today. Traditional tire sealants contain large chunks of rubber particles that are incapable of sealing small holes in a tire, yet they will readily seal a large and dangerous hole or gash. Conversely, Puncturesafe contains only small rubber granules and synthetic fibers that when interlocked in a puncture are extremely strong. PunctureSafe will only seal punctures in the tread area that are safe to seal and which have been caused by puncturing objects no larger than 6mm in diameter and only if the hole is shrinking in size because neither excessive tire rubber has been lost or cord damage has occurred. These small punctures account for 95% of today’s punctures in high-speed vehicles. For any larger puncture, either with or without cord damage, PunctureSafe will just slowly bleed through the hole giving a controlled deflation. In these circumstances, the air pressure loss in the tire will either stop or slow down at the lower pressures of 10 to 15 PSI, dependent on the severity of the puncture. This slower loss of air pressure prevents damaged rims and enables the driver/rider to maintain control and possible continuation of the journey, thereby removing the vehicle from a potentially dangerous location. PunctureSafe will not seal a puncture in the sidewall because the sidewall is much thinner and more flexible, therefore in the event of sidewall punctures a controlled deflation will usually occur.

Gives better coverage throughout the inner tire

Traditional tire sealants do not cover 100% of the crown area in a high-speed tire-at best they usually only cover 60%, which becomes less as the vehicle increases in speed because more of the tire sealant is driven to the center area creating a mound that can cause vibration at the higher speeds. One of the components of PunctureSafe is a polymer gel (FlexxaGel™), which has an affinity to adhere to rubber even in a vehicle moving at very high speed. Although “FlexxaGel™” behaves like a glue and has properties similar to glue, it is not a glue. When the lateral movement of a vehicle throws the excess PunctureSafe over the crown area and sideways up the inner sidewalls of the tire, the adhesive properties of “FlexxaGel™” allows PunctureSafe to cling evenly over more of the inner tire surface at all speeds. Although the gel will immediately cover the whole area of the crown and shoulder areas, a settling-in period of 1500+ miles is required to activate the FlexxaGel™ for sidewall coverage. This maintained inner tire coverage at speed gives added heat dispersion to the rim via sidewall coverage due to conduction. Heat dispersion to the rim allows a cooler inner tire and cool tires are less susceptible to punctures. The gel’s ability to seal porosity leaks over the inner tire helps maintain tire pressure and the tire becomes safer with the added bonus of extended tire life. The incorporation of “FlexxaGel™” into the process also gives the finished sealant incredible elastic properties enabling it to stretch and flex, covering more of the inner tire with increasing speed. The PunctureSafe gel will relax in a stationary vehicle covering less of the inner tire. “FlexxaGel™” is exclusively manufactured at our Devon facility and is one of our most closely guarded trade secrets.

Withstands the heat and stress in a high-speed tire

Unlike traditional tire sealants, PunctureSafe’s concentrated polymer gel formulation containing over a dozen technically advanced polymers, rubber, and fiber fillers, will not separate, ball up, or dry up – thereby withstanding the extreme heat and centrifugal forces that can be created in the hostile environment of a very high-speed tire. In a closely guarded proprietary process, PunctureSafe is manufactured to stay liquid in a high-speed tire for the entire lifetime of the tire, irrespective of its use. Compared with traditional tire sealants, the Thixotropic qualities of the PunctureSafe polymers allow change from a very viscous gel to a thin liquid when the vehicle is at speed, yet returning immediately to a viscous gel when the vehicle comes to rest, and it is this feature that helps stabilize the polymers from eventual breakdown. Many traditional tire sealants pool on the bottom of a tire in a stationary vehicle causing vibration with each forward movement, but PunctureSafe stays firmly coated over the inner tire. PunctureSafe’s ability and performance are not diminished by speed, distance, or time.

These qualities alone put PunctureSafe in a league of its own.

Why Does PunctureSafe Outperform Other Sealants?

PunctureSafe is not like a tire sealant, it is “a revolutionary new product.”

Why PunctureSafe performs, while others fail

Traditional tire sealants are simple inexpensive products, formulated with as little as 4 ingredients, very similar to wallpaper paste, and containing particles of shredded tires, that “temporarily” clog up a hole in a tire. When they are applied in a high-speed tire, because of heat, and centrifugal forces, they break down and dry up, thus rendering them ineffective. This may be detrimental to the tire long term, and they may also rust or corrode rims, and steel belts. Whereas, PunctureSafe, is a “concentrated viscous gel,” consisting of many polymer gel ingredients in a comprehensive and secret formulation. Our specially manufactured “coarse surface” synthetic fibers interlock together in the puncture, which cures, and “permanently” seals punctures in a tire with the help of the heat that is generated through contact with the road. PunctureSafe is a proprietary formulation having unique properties. This means it goes from a gel to a liquid with centrifugal forces and then immediately snaps back to a gel just before coming to rest. That’s why PunctureSafe always stays dispersed on the inner tire instead of pooling on the bottom, which is one of the many reasons it works at high speed. Once PunctureSafe has been installed, it conditions the tire making the rubber supple, thereby reducing cracking, deterioration, and porosity. Any hole caused by puncturing objects up to 6 mm(high-speed grade,) 15 mm (medium-speed grade), and 20 mm (low-speed grade), will be permanently sealed by Puncturesafe.

PunctureSafe does not have any of the failings that previous and many present-day products have. Apart from drying and balling up in the tire, the biggest failings of traditional tire sealants in a high-speed tire are the inability to seal small holes, but the ability to seal a large dangerous hole or cut, because they contain large chunks of chopped-up old rubber tires. The sealing capabilities of PunctureSafe are unparalleled by any tire sealant worldwide. PunctureSafe seals are positive and secure, thereby transforming any tire into a self-sealing tire. PunctureSafe is capable of sealing punctures as long as the puncturing object has not severely damaged and/or weakened the tire’s structural integrity. PunctureSafe cannot create a secure seal in any tire that has major internal damage, regardless of the puncturing object’s diameter. If the casing becomes damaged or weakened to the point of being unsafe, the PunctureSafe formulation has been designed to slowly bleed regardless of how small the wound may be, giving a controlled deflation. Cords are instrumental in rubber recovery, and without cords, a tire will inflate like a balloon. When cords are severely cut, the hole in the tire will enlarge with increased air pressure. So, in a moving vehicle, Puncturesafe will assist to give this controlled deflation as the hole shrinks with increasing air loss and reducing air pressure.

Understanding

PunctureSafe

Understanding PunctureSafe and a basic guide to tire sealants by the PunctureSafe Technical officer

(This article was published in the BMW Club Magazine after a request from the editor)

With the recent popularity of PunctureSafe, and with so much lack of knowledge about our product, I have been asked to write an article about how PunctureSafe functions inside a high-speed tire. I will also give a little guidance as to what to look for when choosing a puncture prevention treatment, whether for high or low-speed use. Sealants in general have been around since the early sixties. While they were primarily manufactured for low-speed markets such as construction, and agricultural use, many people attempted to inject them into their cars and motorcycle tires resulting in problems that were costly and sometimes dangerous. This was fueled by unscrupulous manufacturers who saw a quick profit.

You can still see these companies today advertising their products suitable for high speed. Inexpensive sealants manufactured for low-speed use have a very basic carrier liquid, very similar to wallpaper paste that contains large chunks of rubber that will bridge a large punctured hole. They are intended to create a temporary plug in an off-road tire, to enable the operator to continue with the use of the vehicle/machine until a tire fitter is able to make a repair at the end of the day. They cost pennies to manufacture and are sold to farmers and builders, who put them into their tires in huge quantities. These sealants contain a high amount of water and slop around at the bottom of the tire, so when they are installed in a high-speed tire (over 20mph) they are extremely hazardous, and many rust wheel rims and corrode alloys. The worst that can happen is that large rubber chunks can log jam in a large punctured hole that has secondary damage, and because the rubber will stay slippery when wet, the seal can fail at high speed.

Even the many sealants that also contain fibers are useless because they usually contain the wrong type of fiber that ball up in a high-speed tire. The inexpensive and inferior polymers in these products will also separate and dry up due to heat after 500 to 2,000 miles. With these sealants, once separation begins, there is no recovery. Another problem that is inherent in many sealants is their inability to disperse throughout the inner tire. They readily flow to the bottom of the tire, almost like water. The fast-rotating tire forces the sealant into a narrow band against the outermost portion of the tire’s inner surface, causing the sealant to remain in the center portion of the tread area, allowing no protection elsewhere. Consequently, porosity and bead leaks continue to exist giving rise to under-inflation. Because low inflation makes tires run hotter and wear faster, they become subject to punctures and road hazard damage. Hot rubber simply has less resistance to cuts and punctures. Although an uneven road surface will cause this type of sealant to splash around, the outwards centrifugal forces will always pull the product back to the center of the tread area. Any punctures that these products seal in a high-speed tire are usually short-lived with failure of the seal inevitable within a month or two due to extreme heat and polymer shrinkage in the puncture.

So, what tire product do you need that will work effectively in a high-speed tire and will be 100% safe? We at PunctureSafe endeavored to formulate a polymer gel that would stay liquid up to speeds of 150 mph, and that would only seal a hole that was safe to seal because it was recovering in size from a puncture because secondary damage had not occurred to the cords, or rubber had not been lost as a result of that puncturing object, which is usual with objects like glass and screws. We managed to formulate a thixotropic liquid gel of over 12 polymers, all working together to withstand extremes of heat and stress forces. Most importantly we developed a combination of special fibers and very small, low-density rubber particles that work with the polymer gel to create a safe product of outstanding abilities. An effective sealant for high speed will be thixotropic and in a gel form. Thixotropic describes a compound of a framework of one kind of particle, which supports other particles within the substance, and is semi-solid or gel-like.

When a force is applied, the bonds between the particles in the suspension become weaker, and the substance loses some of its structure. It then behaves more like a liquid and the viscosity decreases as the sheer force increases, returning to the gel state upon standing. PunctureSafe’s thixotropic sealant gel is manufactured by a secret proprietary process, not mixed like a cake recipe. Good sealants should not be ethylene glycol based and contain a combination of fibers, particulates, pigments, adhesion agents, rust/corrosion inhibitors, thixotropes, viscosity control agents, and PH retainers, which all come together to form an air-impervious plug-in the event of a puncture. The plug should maintain flexibility because of plasticizing additives, so it flexes with the tire and positively remains in place sealing the puncture. Though thixotropic, such formulas regain their fluidity due to kinetic energy from tire revolution. Adhesion agents should be added to hold the sealant in place after the vehicle has stopped. An effective sealing compound remains in a thixotropic gel state and will resist flowing to the bottom of the tire by actually clinging to the entire inner surface, stretching as the centrifugal forces increase, acting as a thermal conductor, transferring heat from areas of higher temperature to areas of lower temperature. This thixotropic state allows the compound to stretch as sheer forces increase and revert back to its original viscosity as the sheer forces diminish, and also prevents the centrifugal force from separating the various polymers. Also, this thixotropic state is what protects the polymer gel, allowing the sealant to last beyond the life of the tire.

In the event of a puncture the sealant is squeezed into the hole assisted by air pressure and capillary action, and as the puncture rolls off the load point, leaves the fibers, particulates, and polymers in the hole to cure. Repeated rotation of the tire under normal load deposits more fibers etc until the seal becomes extremely tight. Fibers, unlike rubber, are very coarse surfaces, and once they have keyed and intertwined together in a hole that is shrinking and has recovered in size, they become very strong and permanent. Our combination blend of small rubber particles and special fiber is extremely safe, compared with chunky rubber when they seal a hole, as they will not bridge a large gap. If cords are cut or rubber has been lost in a puncture, then fibers will slowly bleed out of the hole giving a controlled deflation. Our fiber blend will only stay in a place where there is a good thickness of the rubber, which is why you will get a controlled deflation with a puncture to the much thinner sidewall. It is the ability of our special blend of fibers, to distinguish what is safe to seal, and what is not, that gave rise to our marketing slogan “PunctureSafe is a clever thinking product.” Any legitimate sealant manufacturer shouldn’t make the claim that a high-speed tire will never go flat with its sealant installed. Otherwise, this raises the question of safety.

95% of punctures are straightforward with nails cleanly penetrating between the cords causing little damage. If a good sealant is present, then the lubrication from the sealant will usually help expel the nail sooner rather than later, helping to avoid secondary damage. When the nail is expelled; the puncture recovers to a tiny hole, and if a good sealant is present within the tire, it will positively seal the hole safely. If the puncturing object is at a bad angle and left in for any length of time, secondary damage may occur, so when the object is removed you should get a controlled and slow deflation. Glass and screws are notorious for causing this tire of damage by cutting the cords and gouging tire rubber away leaving a cavity, which is not usually seen by the naked eye. In this instance, a good reputable sealant will slowly and safely let the tire down in a controlled manner and sometimes halt the air loss at about 10 to 15psi, which could allow the driver/rider to remove the vehicle from a possibly dangerous location. With the correct amount of sealant installed, tire balance will not be upset in a well-balanced wheel. With a bad sealant fitted to an unbalanced or out-of-round tire, you will get the effect of hydrodynamics (motion of fluids). An out-of-balance wheel rotates eccentrically, causing a dislocation of mass toward the center of gravity, but away from the geometric center of the wheel, producing vibration. In a well-balanced tire, thixotropic sealant gels contain adhesion agents that can dampen the occasional shudder or vibration because they are distributed by centrifugal force to the center of gravity, causing the geometric center and the center of gravity to become aligned.

Why is PunctureSafe Beneficial in a Tire?

The majority of flats and blow-outs are a result of driver negligence. The number one cause being excessive heat generated from under inflation. The overheated, under inflated tire becomes soft and can be penetrated very easily. However, under inflation creates additional problems such as tread and ply separation, all of which is primarily caused by porosity (natural air migration) which exists in all tires to some degree. PunctureSafe eliminates air migration and prevents the majority of damage created by under inflation, thereby preventing most related blow-outs. Once Puncturesafe has been installed, it conditions the tire making the rubber supple, thereby helping to reduce sidewall cracking, deterioration, and porosity.

Heat in a tire is critical, because it helps with traction (helps the tyre stick to the road) but excessive heat is a major problem. Heat on the outside of the tire caused by contact with the road eventually makes its way to the inside causing hotspots, but because rubber is a poor conductor, very little of this heat makes its way to the rim, which is a wheels natural heat sink. Eventually, this heat inside, builds up, causing punctures, blowouts, excessive tire wear, and eventual failure. This is where PunctureSafe can help. The PunctureSafe treatment deals with this heat in two ways, it disperses then conducts the heat to the rim, via Puncturesafe’s liquid inner tire coverage, and also due to the fact a little of the secret liquid polymer formulation within the product vapourises whilst the vehicle is in motion, and the heat from this vapour is transferred by condensation to the rim with contact, where it is then passed to the outside environment. What you have now, is a perfectly performing tire, which has the correct temperature on the outside to maintain traction, and cool on the inside, which will help stop tire failure and help extend tyre life considerably.

Puncturesafe’s proprietary process does not use any glue to make a seal, so PunctureSafe is the answer to the problem of the patch that fails due to excessive heat. On the contrary heat is very beneficial to this process, therefore the seal cannot fail due to heat. If the casing becomes damaged or weakened to the point of being unsafe, the PunctureSafe formulation has been designed to slowly bleed regardless of how small the puncture may be, giving a controlled deflation. Cords are instrumental in rubber recovery, and without cords a tire will blow up like a balloon. When cords are severely cut, the hole in the tire will enlarge with increased air pressure, so in a moving vehicle, PunctureSafe will assist to give this controlled deflation as the hole shrinks with increasing air loss and reducing air pressure. With Puncturesafe, and a controlled deflation, a tyre will deflate at a rate depending on the extent of the damage, then as the tyre reaches the lower pressures of 10 to 15 psi, a severe slow down or halt in air loss will be experienced as PunctureSafe’s unique formulation and synthetic fibres are now log jamming in a puncture that is now shrinking in size because of these much lower air pressures. You could now be running on a soft tire instead of the wheel rim, which could mean the difference between keeping control or losing control. This is possible because we do not use chopped up rubber tires in our formulation, we use small particle size soft rubber and 5 different sizes of specially manufactured “course surface” synthetic fibres which interlock tightly together in the puncture.

PunctureSafe’s abilities and performance is not diminished by speed, distance or time

No excessive heat, no punctures,no excessive tire wear.

Key Attributes

Extends tyre life

PunctureSafe maintains air pressure, retards aging within the casing, reduces heat build-up and increases tyre life.

Protects against under-inflation

PunctureSafe has the ability to eliminate porosity, air migration and seepage, thereby allowing the tire to maintain proper air pressure, which in turn will prevent rolling resistance and heat build-up, the biggest cause of high fuel consumption and tire failure. For retreaders this also prevents the inception of most tread separations & ruptures.

Heat reduction

PunctureSafe assists in protecting tires from devastating heat build-up, which is associated with the friction caused by underinflation, and/or overloading. PunctureSafe contains specific ingredients that aid in conducting heat away from the tire, by transmitting additional heat to the rim (which is the tire’s natural heat sink), resulting in a cooler running tire for any type of equipment or vehicle, regardless of use.

Safety Factor

PunctureSafe provides safety factors that are not found in any tire. PunctureSafe will not mask or hide the damage that has breached the integrity of the tire. PunctureSafe is specially formulated to allow any serious puncture (potentially dangerous) to slowly deflate in a controlled manner. This attribute provides safety and aids in alleviating the hazards associated with blowouts. PunctureSafe cannot create a secure seal in any tire that has major internal damage, regardless of the puncturing object’s diameter. This is because PunctureSafe needs rubber recovery in order to work effectively. Cords play a vital part in rubber recovery, but in a puncture that has damaged cords PunctureSafe and air will slowly bleed out of the tire giving the driver a controlled deflation.

Lasts the life of the tire

PunctureSafe’s proprietary process protects the sealant against heat and provides the ability to overcome the centrifugal force of a rotating tire. PunctureSafe’s abilities & performance do not diminish with speed, distance, or time.

Protects the entire inner surface of the tire

PunctureSafe provides a coating that clings to more of the inner tire, thereby providing protection for the tire at all times.

Positive sealing capabilities

PunctureSafe seals are positive and secure, thereby transforming any tire into a self-sealing tire. PunctureSafe is capable of sealing tread area punctures caused by puncturing objects up to 6 mm in diameter, as long as the puncturing object has not severely damaged and/or weakened the tire’s structural integrity. PunctureSafe cannot create a secure seal in any tire that has major internal damage, regardless of the puncturing object’s diameter.

Water-soluble (for easy cleanout)

PunctureSafe is completely water-soluble in its liquid state and leaves no residue when rinsed with plain water. Yet it will not dissolve within a puncture after it has cured. Standard repairing procedures can be utilized without additional effort.

Protection against rust and corrosion

PunctureSafe contains a complete rust and corrosion inhibiting system that not only protects steel and alloy wheels, but in a puncture, PunctureSafe’s proprietary process will also protect steel belts. Outside contaminants are prevented from leaching back into the puncture, which would cause the steel belts to rust and the plies to separate. Without PunctureSafe’s protection, the contaminants would quickly destroy valuable casings.

Cannot create a balance problem

Treating a tire with the recommended amount of PunctureSafe does not provide for an excessive amount of product to accumulate in the tread area, therefore the tire is not subjected to a mass of substance (common with many tire sealants) that would create an imbalance. PunctureSafe cannot create an imbalance due to the ability to evenly coat the inner surfaces of the tire subjected to normal centrifugal force.

If the suspension is worn beyond specified tolerance, or a tire/rim assembly is not balanced and/or trued, the abnormal centrifugal force generated will have enough gravitational force to pull PunctureSafe off the vertical surfaces and collect in the problem area thereby increasing the “existing” imbalance problem. If the problem is severe enough the driver will feel a vibration. The vibration indicates that a problem pre-existed in the tire assembly or suspension prior to installing Puncturesafe.

Eliminates most flats and blowouts

The majority of flats and blowouts are a result of driver negligence. The number one cause is excessive heat generated from underinflation. The overheated, under-inflated tire becomes soft and can be penetrated very easily. However, underinflation creates additional problems such as tread separations, ply separations, and tread ruptures. All of the above is primarily caused by porosity (natural air migration) which exists in all tires to some degree.

PunctureSafe eliminates air migration and prevents the majority of damage created by underinflation, thereby preventing most related blowouts. The sealing capabilities of PunctureSafe are unparalleled by any tire sealant, worldwide.

Will not void tire warranty

Tire manufacturers state that tire sealants do not void their warranties unless it can be proved that the additive caused a problem with the tire structure. PunctureSafe’s polymer composition is completely compatible with all tire components.

Compatible with all retread methods

PunctureSafe conditions the casing and retards aging. Plus, the ability to be thoroughly cleaned out of the tire assures no hindrance for inspection. The product is non-toxic, non-hazardous, non-flammable, does not present a disposal problem, and has no compatibility problems.

How Does PunctureSafe Function Inside a Tire?

It is very important that you understand two aspects regarding the performance characteristics of a tire, in order to fully comprehend how PunctureSafe Tire Life Extender/Conditioner actually functions, along with and as part of the tire.

What is rubber recovery?

Rubber recovery within a tire is very important in conjunction with PunctureSafe. When a tire is punctured, the rubber is forced open by the penetrating object. The puncture is actually much smaller than the puncturing object.

Rubber has memory and it will recover to its original shape after being subjected to adverse conditions or stress factors. When the penetrating object is removed, the rubber recovers and the puncture closes (a tire that is old, worn out and/or dry-rotted will have little or no rubber recovery).

A penetrating object left in a tire for any extended period of time causes the rubber to temporarily lose its ability to recover. After removing the puncturing object, it is recommended to immediately flex the tire to reactivate the rubber’s memory. As the puncture closes, PunctureSafe is held in place by the strength and integrity of the tire and will then create a positive secure seal.

What is tire flexing?

Tires are constantly flexing when a vehicle is driven. The weight of the vehicle, the irregular surface of the road, and the turning of the tires create a substantial amount of flexing.

Once the puncturing object is removed, it is important for the PunctureSafe seal to be forced into and through a puncture. Once this is accomplished the seal cures and becomes a positively secure seal.

Manual tire flexing (off the vehicle) can be accomplished by removing the puncturing object and then striking the tire several times with a mallet around the puncture area and/or bouncing the tire against the ground. This method creates a temporary seal that will become positive once the tire is installed onto the vehicle and driven approximately 3 to 5 miles.

Is it necessary for you to understand tire construction?

NO! There are many variables in tire construction. In order for a tire sealant to function properly the tire sealant manufacturer must have knowledge of the sealant and tire compatibility, plus have the knowledge and ability to perform exhaustive testing that will assure that the sealant new or used is compatible.

Compatibility and chemical composition are important when a sealant is new in order to meet Health and Safety requirements, but most important is what happens to the tire sealant formulation after it has run a few thousand miles, and is exposed to the normal heat in a tire and the shear and stress that results from the centrifugal force generated in a rolling tire.

Most generic tire sealants can become toxic and/or an environmental hazard. Heat build-up is an important factor and the primary reason average generic tire sealants fail to perform as claimed.

How does PunctureSafe produce a positive/secure seal?

Once the initial driving/usage period has been attained (3 to 5 miles), Puncturesafe will be distributed over the crown area and after 1500+ miles throughout more of the inner surface of the tire. PunctureSafe makes a very thin coating that has the ability to remain suspended onto the tire.

It’s PunctureSafe’s proprietary process that prevents the formulation from separating and/or migrating to the tread area.

PunctureSafe is a liquid coating that conditions the inner surface and eliminates porosity and bead leaks as minute amounts of air attempt to escape. PunctureSafe continuously stands on guard to protect tires against air loss from punctures for the tire’s legal tread life.

When a tire is punctured, PunctureSafe is forced against and around the puncturing object by the inner air pressure, thereby preventing air from escaping.

If the puncturing object is thrown out of the tire by centrifugal force or is pulled out, the inside air forces PunctureSafe into the puncture and immediately stops air loss. Special fibers entwine, forming a seal, then as the rubber recovers (see rubber recovery), aided by the flexing of the rotating tire, the inner air pressure forces the seal well into and through the puncture.

Once PunctureSafe is exposed to outside air, a unique curing process begins. The seal extends well into and through the puncture and once cured provides a seal that is impervious to water.

The cured seal is then transposed into a positive rubberized seal, thereby protecting the inner casing and steel belts by preventing outside contaminants from leaching into the wound.

Will PunctureSafe cure or harden the inside of the tire?

People often ask “If PunctureSafe cures from exposure to outside air, then why does it not cure by the air inside of the tire?”

As the vehicle is driven and the temperature of the tire increases, a portion of PunctureSafe’s liquid base evaporates within the tire’s inner air cavity, as the tire cools, the vaporized liquid condensates back into the formula. The inside air actually becomes part of the PunctureSafe system. The sealed air chamber prevents outside air from entering or inside air from escaping. Constant air pressure resetting is not required. Tires and air pressure should be inspected during routine maintenance.

Why does PunctureSafe not cause a balance problem?

It is extremely important to understand how PunctureSafe’s proprietary process, not found in any other tire sealant, prevents any balance issues prevalent in the majority of other sealants.

PunctureSafe clings to the inner surface of a properly balanced and true (round) tire. The centrifugal force that is created within a high-speed tire actually stretches PunctureSafe much like a rubber band; however, it will not pull PunctureSafe off the inner surface of a properly balanced tire.

A sufficiently out-of-round and/or out-of-balance tire can create enough adverse force that could pull the coating of PunctureSafe from the tire’s inner sidewalls. If a tire requires an excessive amount of weight to be installed to achieve a good reading on the balancer, the tire should be inspected for defects and corrected prior to installing PunctureSafe. PunctureSafe cannot correct an existing problem and may aggravate an adverse situation.

The proper amount of PunctureSafe for high-speed vehicles has been scientifically calculated to provide the proper coating to the inner surface of the tire, allowing for absorption into the casing, yet still, maintaining a reserve.

The reserve (approximately 20% of the installed amount) is extra PunctureSafe that will shift/move. Only the reserve will settle to the bottom of the tire when the vehicle stops. The reserve constantly redistributes as the tire rotates, thereby continually providing an even coating. Each time a puncture occurs, a small amount of reserve is used.

Tire pressure monitoring systems

Caution – when fitting Puncturesafe you may cause the sensor to be coated and thus affect its performance. We recommend that once the installation is complete you inflate the tire to the correct pressure (with the valve core not in situ) then remove the airline to get a powerful blast of air that will clean any sealant left in the valve.

We supply a tire sealant for sealing punctures in the tire of a vehicle, and because Tire pressure monitoring systems can be fickle and prone to failure with or without a sealant present, we advise that you take a cautious approach when fitting our puncture prevention treatment, we advise that the installation is done with the utmost of knowledge. Problems with tire pressure monitoring systems in conjunction with the installation of a tire sealant/puncture prevention treatment are extremely small compared with the millions of tire sealant installations carried out all over the world yearly.

Some ‘Direct’ TPMS have small-bore valves that will not allow the regular sealant to enter. Puncturesafe US recommends that you consult your vehicle manufacturer to check whether their internal TPMS system is sealant-friendly before fitting a puncture prevention treatment.

External ‘Indirect’ TPMS, which measures the speed of each wheel/tire and uses regular valves, is of course always puncture prevention treatment compatible.